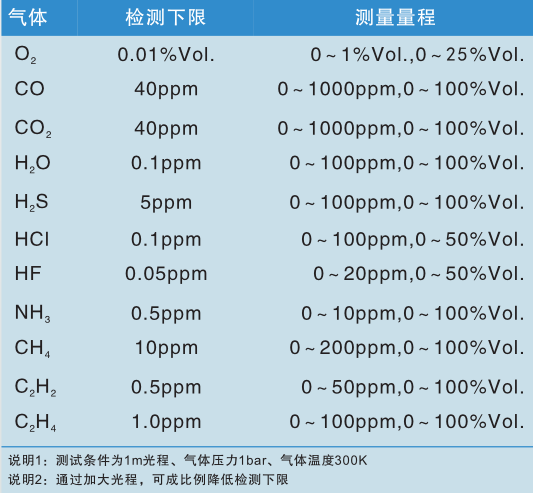

Measurement range:

1. Composition of laser gas analyzer

imported laser detector assembly

Multiple reflection air chamber

Compensation and calibration module

7-inch touch screen and circuit

Multiple reflection chamber

We use the whole process of high temperature measurement, through the isolation technology, the measured gas is introduced into the 200 degree high temperature gas chamber, and the laser is irradiated into the gas chamber. The air chamber has a unique design, with a variety of built-in reflectors, which can reflect the light multiple times, increase the optical path, up to 12 meters, greatly improving the measurement accuracy.

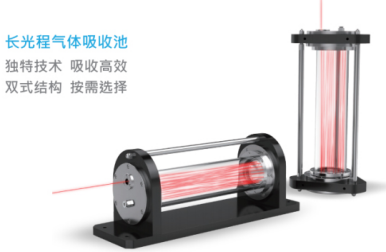

The self-developed long optical path gas absorption cell is suitable for the spectral analysis and detection of a variety of common gas samples. The unique mirror design technology makes the laser beam form multiple reflections in the absorption tank, and the effective optical path reaches tens of meters in a small space, so as to realize the efficient absorption of light in small volume gas samples. Compared with the traditional gas chamber, it is more stable, more resistant to beam separation, small size, simple installation and easy operation, which is very suitable for the laboratory trace gas analysis, industrial process gas detection, environmental gas monitoring, biochemical medicine spectral analysis and other fields.

Characteristic

√ full transparent air chamber, online inspection of optical alignment, easy to adjust

√ two air chamber States, which can be switched between open state and closed state

√ in the closed state, the air pressure can be as low as tens of pascals, effectively reducing the overlapping interference between spectral lines

√ laser inlet and outlet can be designed on the same side or both sides of the instrument according to the actual use requirements

Two types of structures, desktop or free type, for users to choose according to their needs

Compensation and calibration module

Linear processing module

It is composed of 32 ARM processor and data block module, in which the calculation model of humidity, temperature and pressure compensation is stored, and the multi-point linear calculation model is stored to ensure the accuracy of measurement.

Intelligent sensor of humidity and pressure

The humidity and pressure sensors can monitor the working condition of the pretreatment system in real time. When the humidity and pressure in the loop sample gas are abnormal, the signal is transmitted to the linear module as soon as possible, and the countermeasures are taken, and an alarm is given to ensure the stability of the pretreatment and the accuracy of the analyzer.

Functions:

1) The system adds temperature compensation, humidity compensation and pressure compensation to ensure the accuracy and stability of the sensor. Multi point linear calibration improves the sensitivity and accuracy of sensor measurement!

2) Different analysis modules (such as HCl) are respectively used for synchronous real-time monitoring of the whole process;

3) On the touch screen, the measured value can be displayed in digital or bar graph mode at the same time;

4) Menu drive, human-computer interface;

5) Multiple interfaces are used to analyze the communication between the system and each main / sub-system, with RS485 and Ethernet interfaces;

6) The output / input module has flexible configuration of digital and analog input / output functions;

7) Automatic diagnosis and alarm function;

7-inch touch screen and circuit

There are no moving parts in the analyzer. The unique system design for the industrial environment greatly enhances the reliability. The analyzer has a friendly human-computer interface, large temperature LCD screen display, menu operation, and can basically master the operation of the instrument without instructions. After preprocessing, the instrument has a long life, convenient maintenance and low operation cost.

◆ System specification

◆ Equipment model: sy-tdls series

◆ Resolution: ± 200ppb

◆ Accuracy (≤±% F.S.): < 1%

◆ Zero drift: ≤± 0.2% · 24h; ≤± 0.5% full scale / cycle.

◆ Zero gas requirement: dry air.

◆ Full range drift: ≤± 0.1% full range / 24h; ≤± 0.2% full range / week.

◆ Standard gas: valid for 1 year

◆ High concentration standard gas: 80% - 100% of full scale value.

◆ Linearity: ≤± 1%.

◆ Analysis method: laser absorption spectrum

◆ Ambient temperature limit (minimum / maximum ℃): -10 ~ 45 ℃

◆ Instrument power consumption: 0.5kva

◆ Alarm output contact: switch value output

◆ Output signal type: 4-20madc rs458

◆ Instrument air consumption (m3 / h): None

◆ Automatic zero calibration cycle (day / time): 4 days / time (can be set by the customer)