Model: aqms-3000 carbon monoxide analyzer

(1) Technical principles

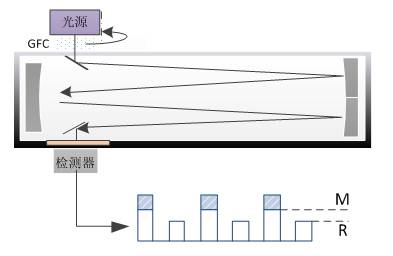

The basic working principle of carbon monoxide analyzer is gas filtration correlation non dispersive infrared method: Based on the absorption of infrared light wave by CO molecule, it conforms to beer Lambert law,

The infrared light with a specific wavelength is preferentially modulated, and then passes through a gas chamber containing high concentration of carbon monoxide and a pure nitrogen gas chamber respectively. When the red light passes through a high concentration of carbon monoxide, the infrared light enters the sample gas chamber, and the co no longer absorbs the infrared light; when it passes through a pure nitrogen gas, the infrared light can be absorbed by the CO in the sample gas, and the information of the sample gas CO concentration is recorded. The measurement signal M and the reference signal R are obtained by the demodulation circuit, and the CO concentration can be calculated according to the M / R.

(2)Technical index

指标 | 数值 |

测定范围 | 0 ~1ppm、0~1,000ppm(可调试) |

单位 | ppb,ppm,ug/m3,mg/m3 |

零点噪声 | <0.02ppm(RMS) |

最低检出限(LDL) | 0.04ppm(RMS) |

零点漂移 | <0.1ppm/24小时 |

量程漂移 | <0.5ppm/24小时 |

响应时间 | <120s |

线性 | <1%/FS |

重复性 | <1% |

采样流量范围 | 800cm3/min±10% |

环境温度 | 5℃~40℃ |

尺寸(H×W×D) | 178mm×432mm×613mm |

重量 | <16kg |

电源 | 200V~240V、50/60Hz、400W |

模拟输出 | 10V、5V、1V、0.1V(可选) |

通讯规格 | RS232、RS485 |

(3)Functional characteristics

■ use of gas filter related technology

■ light chamber with temperature control and vibration protection

■ built in AC mechanical vacuum pump

■ multi function operation by microprocessor

■ bidirectional RS-232 port for remote control

■ digital status output instrument working parameters

■ with temperature compensation and pressure compensation options

■ task software allows monitoring of test data during operation

■ stable flow control system

■ use electronic flow sensor to monitor sample gas flow

■ continuous self check with alarm function

■ self check function of light source intensity attenuation

■ adaptive signal filtering technology to optimize response time

■ automatic monitoring of instrument parameters

■ color display, touch screen operation

■ large capacity memory, automatic storage of historical data